Singer 401a Instruction Manual: A Comprehensive Guide

Discover the enduring legacy of the Singer 401a with this detailed manual‚ offering guidance from basic operations to advanced techniques for all skill levels․

The Singer 401a‚ a cornerstone of sewing history since 1851‚ represents Isaac Singer’s innovative spirit․ This machine‚ renowned for its durability and reliability‚ quickly became a household name․ This manual serves as a comprehensive resource for both novice and experienced users‚ unlocking the full potential of this classic sewing machine․

Historical Significance of the 401a

Introduced in the mid-20th century‚ the Singer 401a quickly gained prominence for its robust construction and versatile capabilities․ It became a staple in homes and sewing businesses alike‚ embodying an era of quality craftsmanship․ Its enduring popularity speaks to Singer’s legacy of innovation and reliability‚ making it a collector’s item today․

Key Features and Specifications

The Singer 401a boasts a powerful motor‚ capable of handling various fabrics․ It features a zigzag stitch‚ adjustable stitch length and width‚ and a reverse lever․ Built with a durable aluminum body‚ it’s known for longevity․ It utilizes a 15-class needle system and a standard bobbin‚ ensuring compatibility and ease of use․

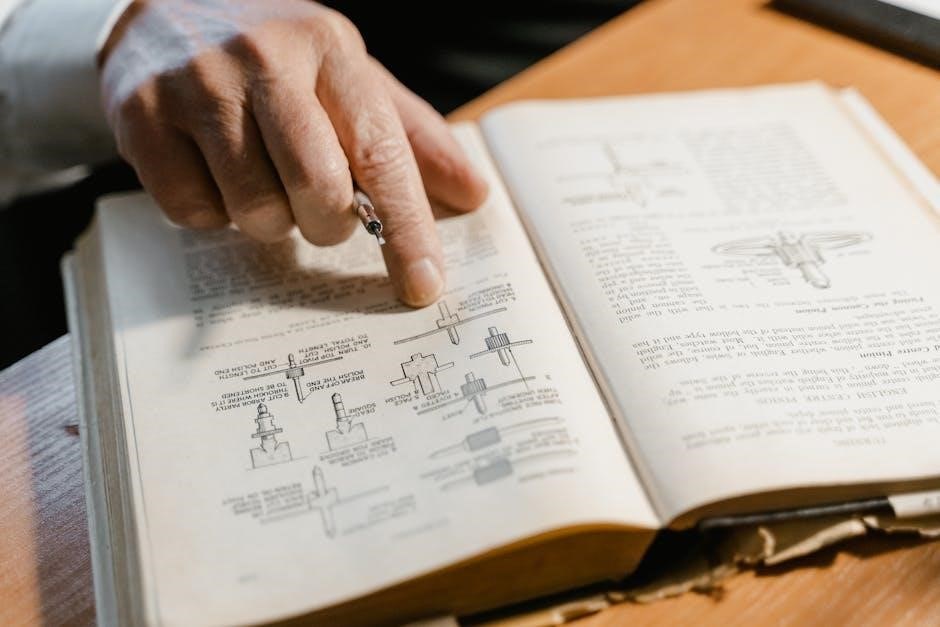

Understanding the Machine Components

Explore the Singer 401a’s robust construction‚ from its motor and handwheel to the needle bar and presser foot‚ vital for seamless sewing experiences․

Identifying the Major Parts

Familiarize yourself with the Singer 401a’s key components: the power switch‚ handwheel‚ spool pin‚ bobbin winder‚ tension dials‚ stitch length control‚ and reverse lever․ Understanding these elements is crucial for operation․ The presser foot‚ needle clamp‚ and feed dogs facilitate fabric movement․ Locate the bobbin case and cover plate for threading․ Knowing each part’s function ensures efficient sewing and maintenance‚ extending the machine’s lifespan and unlocking its full potential․

The Bobbin System Explained

The Singer 401a utilizes a horizontal rotating bobbin․ Properly winding the bobbin is essential for consistent stitch quality․ Insert the bobbin into its case‚ ensuring smooth rotation and correct threading through the tension spring․ A correctly installed bobbin prevents skipped stitches and thread nests․ Regularly check for lint and debris‚ cleaning as needed to maintain optimal performance and prevent jamming during sewing operations․

Needle and Presser Foot Mechanics

Understanding the interplay between the needle and presser foot is crucial․ The 401a’s mechanics ensure consistent fabric feed․ Select the correct needle type for your fabric weight – universal‚ ballpoint‚ or denim․ Adjust presser foot pressure for optimal control; lighter fabrics need less pressure․ Ensure the needle is correctly inserted and not bent‚ preventing damage and ensuring smooth stitch formation․

Threading the Singer 401a

Master the threading process for consistent stitches! Follow the numbered diagrams carefully‚ ensuring the thread flows smoothly through all guides and tension discs․

Step-by-Step Threading Guide

Begin by raising the presser foot and ensuring the needle is in its highest position․ Place the spool of thread on the spool pin‚ securing it with a cap․ Guide the thread through the first thread guide‚ then down and around the tension disc․

Next‚ continue threading through the take-up lever‚ ensuring it’s fully engaged․ Proceed down to the needle bar thread guide and finally‚ thread the needle from front to back․ Proper threading is crucial for optimal sewing performance․

Winding the Bobbin

Start by placing the spool of thread on the spool pin and guiding the thread to the bobbin winder tension disc․ Position the bobbin onto the bobbin winder spindle‚ ensuring it clicks into place․

Engage the bobbin winder by pushing it to the right․ Press the foot pedal gently to begin winding; stop when the bobbin is full․ Disengage the winder and remove the bobbin for use in your sewing projects․

Troubleshooting Threading Issues

If encountering threading problems‚ retrace each step‚ ensuring the presser foot is up and the thread is properly seated in all guides and discs․ Check for lint or debris obstructing the thread path․

Verify correct bobbin insertion and tension settings․ A tangled nest of thread often indicates improper threading or tension imbalance; adjust accordingly for smooth operation․

Basic Sewing Operations

Master fundamental techniques like straight and zigzag stitching‚ essential for various projects‚ alongside adjustments for stitch length and width control․

Straight Stitching Techniques

Achieve precise seams with consistent stitch length‚ crucial for garment construction and quilting․ Begin by correctly threading the machine and selecting a suitable needle․ Practice guiding the fabric smoothly‚ maintaining a consistent seam allowance․

Experiment with different stitch lengths for varying fabric weights – shorter for delicate materials‚ longer for heavier ones․ Utilize the presser foot to ensure even fabric feed‚ resulting in professional-looking straight stitches every time․

Zigzag Stitching Applications

Unlock versatility with the Singer 401a’s zigzag stitch! Ideal for finishing raw edges to prevent fraying‚ creating decorative embellishments‚ and sewing stretch fabrics․ Adjust stitch width for varied effects – narrow for reinforcement‚ wider for decorative trims․

Master techniques like satin stitch for appliqué and blind hems for invisible closures․ Explore creative possibilities beyond basic seams with this adaptable stitch․

Adjusting Stitch Length and Width

Precisely control your stitches on the Singer 401a! Stitch length dictates durability – shorter for delicate fabrics‚ longer for heavier materials․ Utilize the designated dials to fine-tune․ Adjust stitch width for zigzag variations‚ impacting decorative effects and seam strength․ Experiment to achieve desired results‚ ensuring proper tension for optimal stitch formation and fabric compatibility․

Advanced Techniques & Accessories

Unlock the 401a’s full potential! Explore specialized presser feet and attachments for embroidery‚ darning‚ and monogramming‚ expanding creative possibilities․

Using Attachments and Presser Feet

The Singer 401a truly shines with its diverse range of available attachments and presser feet․ These tools dramatically expand the machine’s capabilities beyond basic sewing․ Explore options like the zigzag foot for decorative stitching‚ a rolled hem foot for delicate edges‚ and various specialized feet for zippers‚ buttonholes‚ and even quilting․

Proper attachment installation is crucial for optimal performance; always consult the manual for specific guidance․ Experimenting with different feet unlocks a world of creative sewing possibilities!

Embroidery Capabilities (with compatible modules)

While the Singer 401a isn’t natively an embroidery machine‚ compatibility with certain optional modules allows for basic monogramming and decorative stitching resembling embroidery․ These modules‚ often sold separately‚ typically include embroidery hoops and design cards․

However‚ modern computerized embroidery machines offer far greater design complexity and automation․ The 401a’s embroidery features are limited compared to dedicated embroidery models․

Darning and Monogramming

The Singer 401a excels at darning socks and garments‚ utilizing its robust mechanics and adjustable stitch settings for seamless repairs․ Monogramming is achievable with optional alphabet attachments‚ allowing personalized embellishments on fabrics․

These features showcase the machine’s versatility beyond basic sewing‚ offering practical solutions for extending the life of clothing and adding custom touches․

Maintenance and Troubleshooting

Ensure longevity with regular cleaning and oiling of key components; address common issues like threading problems with our detailed troubleshooting guide․

Regular Cleaning Procedures

Maintaining your Singer 401a involves consistent cleaning to remove lint and debris․ Power off and unplug the machine before starting․ Use a brush to clear lint from the bobbin area‚ feed dogs‚ and around the needle plate․ A small vacuum can also be helpful․ Wipe down exterior surfaces with a soft cloth․

Avoid using liquid cleaners directly on the machine; instead‚ dampen the cloth lightly․ Regular cleaning prevents jams and ensures smooth operation‚ extending the life of your reliable sewing companion․

Oil Points and Lubrication

Proper lubrication is crucial for the Singer 401a’s longevity․ Locate the designated oil points – typically around the bobbin area‚ gears‚ and moving linkages․ Apply a few drops of sewing machine oil sparingly‚ avoiding over-oiling․

Ensure the oil reaches the internal components by operating the machine slowly after application․ Wipe away any excess oil to prevent staining fabric․ Regular oiling maintains smooth‚ quiet operation․

Common Problems and Solutions

Encountering issues? Thread bunching often indicates incorrect threading or bobbin insertion․ A skipped stitch may signal a dull or incorrect needle․ If the machine jams‚ stop immediately and clear lint buildup․

For persistent problems‚ consult the full manual or seek professional repair․ Regular cleaning and proper lubrication prevent many common malfunctions‚ ensuring smooth sewing performance․

Finding Replacement Parts and Manuals

Locate original Singer resources and online retailers for manuals and parts․ Maintaining your 401a is easier with readily available support and components․

Official Singer Resources for Manuals

Access free downloadable user manuals‚ stitch guides‚ and machine updates directly from the official Singer website․ These resources cover a wide range of Singer‚ Husqvarna Viking‚ and PFAFF products‚ ensuring you have the latest information for your 401a․

Explore the manuals and updates page for comprehensive guides to keep your sewing machine running smoothly and efficiently‚ maximizing its potential for years to come․

Locating Replacement Parts Online

Finding replacement parts for your Singer 401a is readily achievable through various online retailers specializing in vintage sewing machine components․ Numerous websites offer a diverse selection of parts‚ ensuring you can maintain and repair your machine effectively․

Explore these online sources to restore functionality and extend the lifespan of your beloved 401a sewing machine․

Dating Your Singer 401a

Determining the manufacturing date of your Singer 401a can be fascinating! The serial number‚ typically found on the machine’s body‚ holds the key․ Online resources and Singer databases allow you to decode this number․

This reveals the year your machine was originally produced‚ adding to its historical significance and value․

Singer 401a vs․ Modern Sewing Machines

Explore the strengths and weaknesses of the 401a compared to contemporary models‚ considering its robust build and simplicity versus modern features․

Advantages of the 401a

The Singer 401a boasts exceptional durability due to its all-metal construction‚ ensuring longevity and reliable performance․ Its mechanical simplicity makes it remarkably easy to maintain and repair‚ often without specialized tools․ Many users appreciate its powerful motor capable of handling heavier fabrics․

Furthermore‚ the 401a’s straightforward design fosters a deeper understanding of sewing mechanics‚ and readily available parts contribute to its continued usability today․

Limitations Compared to Newer Models

While robust‚ the Singer 401a lacks the automated features common in modern machines‚ such as automatic needle threading or programmable stitch patterns․ It has a limited stitch selection compared to contemporary sewing machines‚ focusing primarily on straight and zigzag stitches․

Additionally‚ it doesn’t offer built-in embroidery capabilities without compatible modules‚ and its operation can require more manual dexterity․

Resources and Support

Find assistance through online forums‚ dedicated communities‚ and professional repair services to maintain and troubleshoot your classic Singer 401a sewing machine․

Online Forums and Communities

Engage with a vibrant network of Singer 401a enthusiasts! Numerous online forums and communities offer invaluable support‚ troubleshooting advice‚ and shared experiences․ These platforms are excellent resources for locating hard-to-find information‚ discovering unique applications‚ and connecting with fellow machine owners․ Users frequently share digitized manuals‚ tips on restoration‚ and solutions to common mechanical issues․ Explore these spaces to unlock the full potential of your vintage Singer!

Professional Repair Services

For complex issues beyond self-repair‚ consider professional Singer 401a restoration and repair services․ Qualified technicians specialize in vintage sewing machine mechanics‚ offering expertise in diagnosing and resolving intricate problems․ These services can include complete overhauls‚ lubrication‚ and replacement of worn parts‚ ensuring your machine’s longevity․ Seek reputable repair shops with proven experience servicing the 401a model․