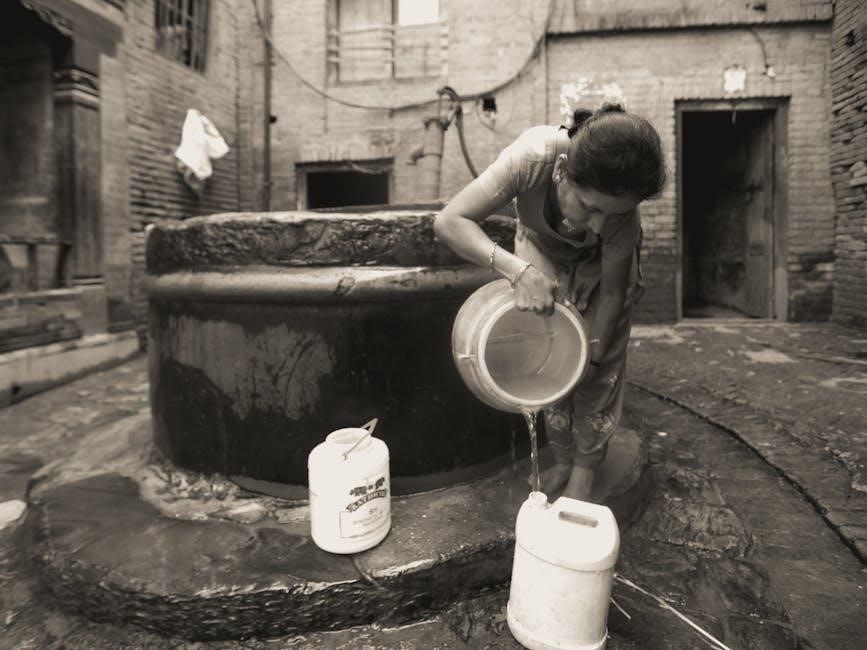

Manual well pumps provide a reliable‚ eco-friendly solution for water supply systems. These devices operate without electricity‚ ensuring consistent access to clean water‚ especially in off-grid or remote areas. Simple‚ cost-effective‚ and sustainable‚ they offer a practical alternative for homeowners seeking independence from electric-powered systems.

Overview of Manual Pumps

Manual well pumps are mechanical devices designed to extract water from wells using human effort. They operate by creating suction or pressure to lift water to the surface. These pumps are simple‚ durable‚ and energy-efficient‚ making them ideal for rural or off-grid locations. They rely on physical operation‚ such as moving a handle‚ to function effectively. This design ensures a sustainable and reliable water supply solution.

Importance in Water Supply Systems

Manual pumps are vital in water supply systems‚ especially in areas without electricity. They provide a consistent and reliable source of clean water for drinking‚ irrigation‚ and household use. Their simplicity and low maintenance make them ideal for remote communities‚ ensuring access to water during emergencies or power outages. This makes them a cornerstone of sustainable water solutions globally.

Types of Manual Pumps

Manual pumps include pitcher‚ suction‚ and jet pumps. They are simple‚ durable‚ and ideal for wells‚ offering reliable water access without electricity‚ perfect for emergencies or remote areas.

Pitcher Pump

The pitcher pump is a traditional manual well pump known for its simplicity and effectiveness. It operates by lifting water from the well using a piston and cylinder mechanism. As the handle is moved up and down‚ the piston creates suction‚ bringing water to the surface through a spout or outlet. This design is durable‚ requires minimal maintenance‚ and is often used in shallow wells or for emergency water supply. Its reliability and low cost make it a popular choice for many homeowners and off-grid applications. Additionally‚ the pitcher pump is environmentally friendly‚ as it does not rely on electricity‚ making it a sustainable option for water access.

Suction Pump

A suction pump is a manual well pump that uses atmospheric pressure to draw water from a well. It operates by creating a vacuum‚ which lifts water through a pipe to the surface. Ideal for shallow wells‚ these pumps are simple‚ durable‚ and easy to install. They require minimal maintenance and are often used in residential settings where water demand is moderate. The suction pump’s reliability and ease of use make it a practical choice for many households‚ especially in areas with accessible water tables.

Jet Pump

A jet pump is a high-pressure manual well pump designed for deeper wells‚ typically beyond the reach of traditional suction pumps. It uses a jet of water to create a vacuum‚ lifting water from greater depths. Durable and efficient‚ jet pumps are ideal for larger households or farms. They require regular maintenance to ensure optimal performance and are often preferred for their versatility in various water supply needs.

Installation Guide

Installing a manual well pump involves selecting the right location‚ ensuring proper alignment‚ and securing the pump. Regular maintenance is essential to prevent contamination and extend lifespan.

Steps for Installation

Installing a manual well pump requires careful planning and execution. Start by selecting a suitable location for the pump‚ ensuring it aligns with the well casing. Assemble the pump according to the manufacturer’s instructions‚ paying attention to the handle‚ cylinder‚ and foot valve. Secure the pump to a stable base to prevent movement. Connect the suction and discharge pipes‚ ensuring proper sealing to avoid leaks. Test the pump by priming it and checking for smooth operation. Finally‚ perform a safety check to ensure all components are securely fastened and functioning correctly.

Considerations and Precautions

When installing a manual well pump‚ consider the well’s depth and water level to ensure the pump’s capacity matches the demand. Check local regulations and ensure the pump is installed on stable ground to prevent tipping. Regularly inspect the pump for wear and tear‚ and keep the surrounding area clean to prevent contamination. Always follow the manufacturer’s guidelines for maintenance and operation to ensure optimal performance and longevity of the pump.

Maintenance and Care

Regular lubrication of moving parts and inspection of seals prevent wear. Clean the pump and surrounding area to avoid contamination. Replace worn parts promptly.

Regular Inspection

Regular inspection ensures optimal performance. Check the handle‚ pumping mechanism‚ and water flow for smooth operation. Look for signs of wear‚ leaks‚ or misalignment. Clean the pump and surrounding area to prevent contamination. Inspect the well casing and screen for damage or blockages. Monitor water quality and flow rate to detect potential issues early. Schedule professional checks annually for deeper evaluation.

Replacing Parts

Replacing parts ensures longevity and efficiency. Regularly inspect and replace worn components like seals‚ gaskets‚ and piston rings to prevent leaks and maintain performance. Lubricate moving parts to reduce friction and wear. Replace the handle or rod if damaged to ensure smooth operation. Always use genuine or compatible parts to avoid compatibility issues and extend the pump’s lifespan effectively.

Advantages of Manual Pumps

Manual pumps are cost-effective‚ energy-efficient‚ and reliable without electricity. They provide sustainable water access‚ reduce environmental impact‚ and offer long-term savings‚ making them ideal for eco-conscious users.

Cost-Effectiveness

Manual well pumps are highly cost-effective‚ requiring minimal initial investment and low maintenance. Unlike electric pumps‚ they eliminate recurring energy costs‚ making them a budget-friendly option for water supply. Their durability and simplicity reduce long-term expenses‚ offering significant savings over time while providing reliable service.

Reliability Without Electricity

Manual well pumps operate independently of electricity‚ ensuring water access during power outages or in remote locations. Their mechanical design provides consistent performance without reliance on external energy sources‚ making them a dependable choice for emergency or off-grid water needs‚ thus enhancing self-sufficiency and resilience in various settings.

Challenges and Limitations

Manual well pumps face depth capacity issues and require physical effort‚ limiting their suitability for deep wells or users with limited strength‚ affecting overall practicality and efficiency.

Depth Capacity Issues

Manual well pumps are limited in their depth capacity‚ typically effective for shallow wells up to 20 feet. Beyond this depth‚ they become inefficient‚ requiring additional mechanisms or electric pumps for deeper water extraction. This limitation makes them less suitable for areas with water tables far below the surface‚ necessitating alternative solutions for reliable water access in such scenarios.

Physical Effort Required

Manual well pumps require consistent physical effort‚ as users must operate a handle to draw water; This can be tiring‚ especially for frequent or large-volume usage. Over time‚ repetitive motion may lead to fatigue or strain‚ making manual pumps less practical for households with high water demands or individuals with limited physical ability‚ despite their eco-friendly nature and cost-effectiveness.

Safety and Precautions

Proper handling and installation of manual well pumps are crucial to prevent contamination and accidents. Regular inspection ensures safe operation and reliability of the water supply system.

Proper Handling Techniques

Proper handling of manual well pumps involves regular maintenance and safe operation; Ensure the pump is installed at the correct depth and aligned properly to avoid damage. Always use clean‚ durable pipes to prevent contamination. Regular lubrication of moving parts is essential for smooth operation. Avoid overexertion when pumping to prevent accidents. Follow manufacturer guidelines for installation and use to ensure longevity and safety.

Preventing Accidents

Preventing accidents with manual well pumps requires careful installation and routine maintenance. Ensure all connections are secure to avoid leaks or mechanical failures. Regularly inspect the pump handle and moving parts for wear and tear. Teach users proper pumping techniques to prevent overexertion injuries. Keep the surrounding area clear of obstacles to minimize tripping hazards. Immediate repair of any damage is crucial for safe operation and longevity.

Cost and Budgeting

Manual well pumps offer an affordable initial investment and low installation costs. Their minimal maintenance requirements reduce long-term expenses‚ making them a budget-friendly solution for water supply needs.

Initial Investment

The initial cost of a manual well pump is generally low compared to electric pumps. Prices vary based on materials and features‚ but most manual pumps are affordable‚ typically ranging from $100 to $500. This upfront expense is often offset by long-term savings on energy and maintenance‚ making them a cost-effective choice for many households.

Long-Term Savings

Manual well pumps offer significant long-term savings due to their low maintenance and energy-free operation. With no electricity costs and minimal repair needs‚ they reduce overall expenses. Their durability ensures they last for years‚ providing a sustainable and economical water solution for homes‚ especially in areas with consistent water tables.

Troubleshooting Common Issues

Manual pumps may face issues like leaks or handle problems. Regular inspection and timely part replacement can prevent major breakdowns‚ ensuring reliable water access.

Leaks and Seals

Leaks in manual well pumps often occur due to worn-out gaskets or loose connections. Regular inspection of seals and O-rings is crucial to prevent water loss and damage. Tightening fittings and replacing damaged parts can resolve most issues. Applying silicone-based lubricants may also extend seal lifespan. Addressing leaks promptly ensures efficient pump operation and maintains water quality over time.

Handle and Mechanism Problems

Manual well pumps may experience handle and mechanism issues due to wear and tear. Loose handle connections or misaligned parts can reduce efficiency. Regular lubrication of moving components and tightening of bolts can prevent such problems. Worn-out linkages or rods should be replaced promptly to avoid further damage. Proper alignment ensures smooth operation and extends the pump’s lifespan‚ minimizing downtime and maintenance costs over time.

Environmental Impact

Manual well pumps are eco-friendly‚ promoting water conservation and sustainability. They operate without electricity‚ reducing carbon emissions and offering a environmentally responsible solution for water access.

Water Conservation

Manual well pumps encourage water conservation by promoting mindful usage. Since they require physical effort‚ they reduce waste and foster efficient water use. Additionally‚ their operation without electricity lowers overall energy consumption‚ aligning with sustainable practices and helping to preserve this vital resource for future generations while maintaining environmental balance.

Sustainability Benefits

Manual well pumps offer significant sustainability benefits by minimizing reliance on electricity‚ reducing carbon emissions‚ and promoting eco-friendly water extraction. Their simple design requires fewer resources for production and maintenance‚ making them an environmentally responsible choice. By conserving energy and water‚ these pumps support long-term sustainability goals and are ideal for those prioritizing green living and reducing their environmental footprint effectively.

DIY Projects and Modifications

Manual well pumps can be customized for enhanced functionality and efficiency. DIY modifications allow users to tailor designs‚ improve mechanisms‚ and integrate sustainable solutions‚ ensuring optimal performance and longevity.

Customizing Your Pump

Customizing a manual well pump involves tailoring components to meet specific needs. Users can adjust handle lengths‚ modify materials for durability‚ or add features like water filtration systems. DIY enthusiasts often integrate solar-powered assists or pressure gauges for better functionality. These modifications enhance efficiency‚ reduce physical effort‚ and ensure a reliable water supply‚ making the pump more adaptable to various environments and requirements.

Improving Efficiency

Enhancing a manual well pump’s efficiency can be achieved through regular maintenance and smart upgrades. Lubricating moving parts‚ ensuring tight seals‚ and using lightweight materials reduce friction and effort. Additionally‚ installing a check valve prevents backflow‚ while optimizing pipe diameter minimizes resistance. These tweaks ensure smoother operation‚ increased water flow‚ and prolonged pump lifespan‚ making it a more sustainable and reliable water solution for users.

Manual well pumps offer a reliable‚ cost-effective‚ and eco-friendly solution for water access. Their simplicity and sustainability make them a valuable investment for long-term water supply needs.

Final Thoughts

Manual well pumps are a reliable and eco-friendly solution for water access. They are cost-effective and ideal for remote or off-grid locations. Proper installation and regular maintenance are essential for optimal performance. These pumps offer a sustainable way to manage water resources‚ making them a valuable investment for long-term use.

Future Considerations

Future advancements in manual well pumps may focus on improving efficiency and reducing physical effort. Innovations like adjustable handles and advanced materials could enhance performance. Integration with smart systems might also optimize water usage and well health. Sustainability will remain a key priority‚ ensuring these pumps continue to serve as a reliable water source for generations.